Description

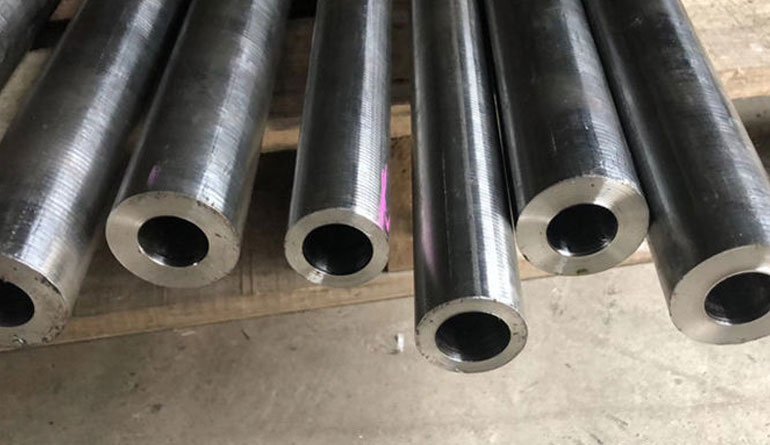

High Nickel Alloys Pipes & Tubes : Specifications | Types | Equivalent | Chemical Composition | Mechanical Properties | Dimensions | Weight Chart High-Performance Nickel Alloy Pipes & Tubes – Nickel Alloy, Inconel, Hastelloy, Monel & Alloy 20 Grades – Seamless, Welded, ERW & EFW Options in Custom Lengths & Diameters – Compliant with International Standards, NACE Certified, ISO 9001:2015 & Third-Party Verified. We are a leading manufacturer and exporter of High Nickel Alloy Pipes and Tubes, engineered for use in highly corrosive, high-temperature, and high-pressure environments. These products are manufactured in compliance with global standards such as ASTM B161, B163, B165, B167, B407, B444, B622, B729, and more. Common materials and grades include Nickel 200/201, Monel 400/K500, Inconel 600/625/718, Incoloy 800/800H/825, Hastelloy C22/C276/B2, and Alloy 20. We offer both seamless and welded forms, with optional annealed or solution-treated conditions to match service requirements. Our product portfolio includes various types such as seamless pipes, welded pipes, heat exchanger tubes, boiler tubes, instrumentation tubing, and U-tubes. Sub-types include cold-drawn, hot-finished, and electropolished variants, depending on end-use. These alloys are composed primarily of Nickel (up to 99%), along with controlled amounts of Chromium, Molybdenum, Iron, Copper, and Cobalt to enhance resistance to oxidizing and reducing agents. The chemical makeup ensures excellent performance in aggressive acids (sulfuric, hydrochloric), seawater, and high-temperature gas environments. Each pipe and tube is clearly marked with essential details such as grade, size, heat number, standard (e.g., ASTM B163), and manufacturer logo, ensuring full traceability. We follow international packing standards using end-caps, waterproof wrapping, bubble…