Description

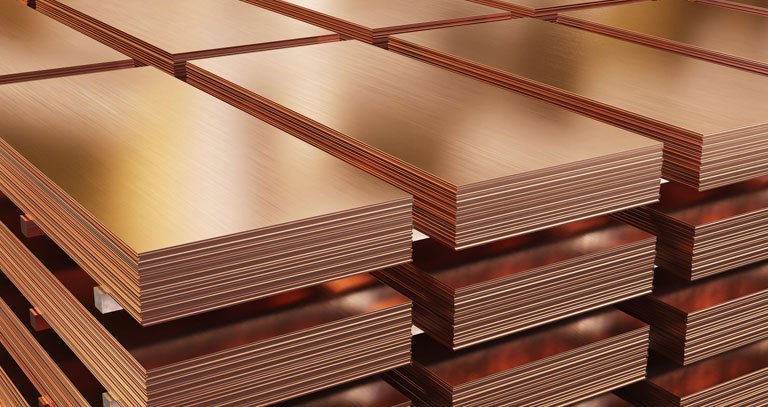

Copper Steel Plates, Sheet, Coils : Specifications | Types | Equivalent | Chemical Composition | Mechanical Properties | Thickness Chart | Weight Chart Premium Oxygen-Free Copper Sheets, Plates & Coils – ASTM B152, B370, B75 Certified – Grades Include ETP C11000, C12000, C12200, C10100, C10200, C10300, C11300 – Offered in Hot Rolled, Cold Rolled, and Mirror Polished Finishes – ISO & PED Approved. Copper Plates, Sheets, and Coils combine the mechanical strength of steel with the excellent electrical and thermal conductivity of copper. Manufactured with precise control over thickness, width, and length, these materials meet international standards such as ASTM B101 and ASTM B152. Common grades include C10100, C11000, C10200 (Electrolytic Tough Pitch Copper) and various copper-clad steel composites. Plates typically range from 2 mm to 50 mm in thickness and up to 2000 mm in width, making them suitable for heavy-duty industrial and electrical applications where both strength and conductivity are critical. Key features of copper products include superior corrosion resistance, good electrical conductivity, and versatile availability in plates, sheets, and coils. These materials offer improved durability compared to pure copper while maintaining much better conductivity than standard steel. Their ability to withstand harsh environments and mechanical wear makes them ideal for electrical connectors, heat exchangers, architectural facades, and industrial machinery components. The advantages of copper steel lie in its enhanced mechanical strength, cost-effectiveness, and ease of fabrication. Unlike pure copper, copper steel has higher tensile strength and better wear resistance, which extends the lifespan of components. Additionally, copper steel is easier to weld and…