Description

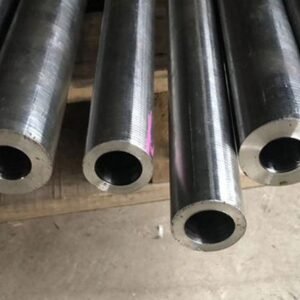

15-5PH, 17-4PH Round Bars : Specifications | Types | Equivalent | Chemical Composition | Mechanical Properties | Size Chart | Weight Chart 15-5PH, 17-4PH SS Round Bars in Black, Bright, Ground, Polished, and Cold Finished Conditions – Available in Custom Sizes and Shapes. MSTAR ENTERPRISES, along with other ISO 9001:2015-certified companies, manufactures and supplies high-quality 15-5PH and 17-4PH round bars, ensuring precision and customization. Available in diameters from 3 mm to 300 mm and lengths up to 6 meters, the bars are offered in forms such as round, square, hexagonal, or flat, with finishes like bright, black, or polished. They comply with international standards including ASTM A564, ASME SA564, AMS 5659 for 15-5PH, and AMS 5643 for 17-4PH, meeting stringent industrial demands with reliability. Technical properties highlight the excellence of these precipitation-hardening martensitic stainless steels. 15-5PH (UNS S15500), with 14.0–15.5% chromium and 3.5–5.5% nickel, features a refined microstructure, enhancing transverse toughness and weldability. 17-4PH (UNS S17400), containing 15.0–17.5% chromium and 3.0–5.0% copper, offers high strength and corrosion resistance akin to 304 stainless steel. Both alloys support heat treatments like H900 for peak hardness or H1150 for improved toughness, achieving tensile strengths up to 1310 MPa. 15-5PH is more forgeable, while 17-4PH excels in high-stress conditions up to 300°C, outperforming 400-series steels in machinability and corrosion resistance. Applications span critical industries due to their durability. In aerospace, they form turbine blades and landing gear; in oil and gas, pump shafts and valves; and in medical, surgical instruments and implants. Nuclear plants use them for waste casks, while…