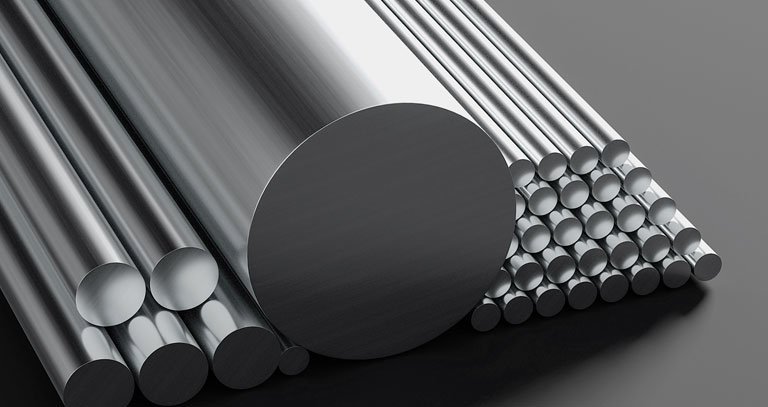

Description

Stainless Steel Centreless Grinding Rods: Specifications | Types | Equivalent | Chemical Composition | Mechanical Properties | Dimensions | Tolerance Premium Quality Stainless Steel Centreless Grinding Rods in Tolerances up to h6 – Supplied in Bright, Peeled, Polished & Cold Drawn Conditions. Stainless Steel Centreless Grinding Rods are precision-engineered rods that undergo a specialized centerless grinding process to achieve superior surface finish, tight dimensional tolerance, and excellent roundness. These rods are manufactured from high-quality stainless steel grades such as 304, 316, 410, 420, 431, 303, and 17-4PH, which are known for their corrosion resistance, strength, and durability. The rods are widely used in industries requiring precision components, including automotive, aerospace, defense, medical, textile machinery, and general engineering. The grinding process removes imperfections and delivers a smooth, accurate, and highly polished surface that is essential for high-precision applications. The manufacturing process begins with the selection of premium stainless steel billets, which are hot rolled or cold drawn into round bars and then ground using a centerless grinding technique. In this process, the rod is supported between a grinding wheel and a regulating wheel, allowing precise control over roundness and straightness without the use of a center point. This results in a uniform diameter across the entire length of the rod, with surface finishes often reaching Ra 0.2 µm or better. Depending on the grade and application, further treatments like heat treatment, annealing, or straightening may be performed to enhance the mechanical properties and dimensional accuracy. Stainless Steel Centreless Grinding Rods are available in a wide range of…